1.1 SUPER-30 - Emergency Response Team:

When seconds count…

At our Ankleshwar plant, we strengthened our Emergency Response Team (ERT), SUPER-30,

by conducting rigorous external training. During the year, we completed 312 mandays of

training consisting of 80% of practical training and 20% classroom training. Further, multiple

emergency response team drills were conducted by the members of SUPER-30.

.jpg)

.png)

.jpg)

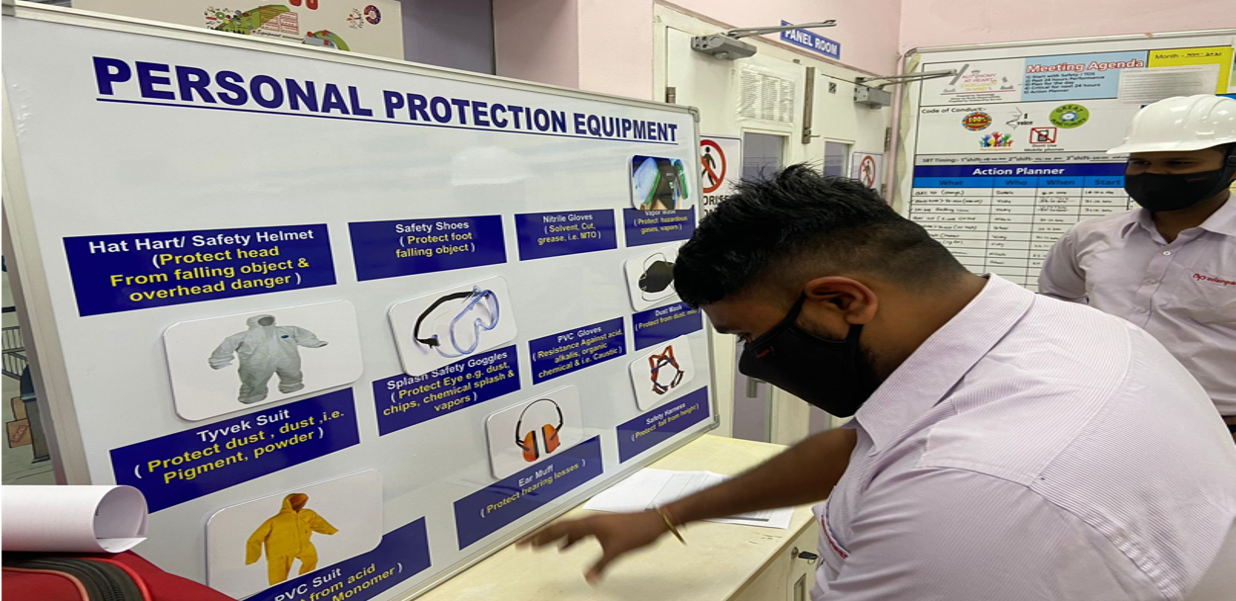

3.1 Safety Awareness Gamification:

An offline interactive dashboard was prepared to aware the employees of electrical

hazards, safe uses of the electrical system, safe working practices and correct uses

of PPEs. Employees are required to match the correct signag

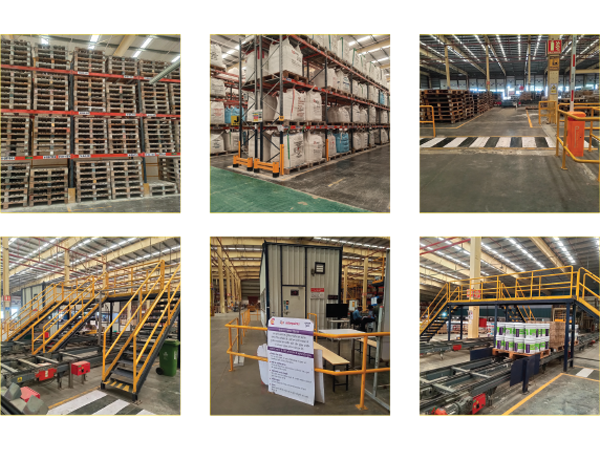

Man-machine interaction are major hazard in our operations. To reduce the man-machine interaction, certain initiatives have been implemented across the plant as depicted in the image below:

Safe Installation And Comissioning of Critical Tank Farms

Safe installation and commissioning of LNG Plant by adopting all the safety protocols/guidelines (statutory approval, sound interlocks, process safety studies etc.)

Design Safety

Basic Engineering

Construction Safety

Process safety studies carried out -

| • | HAZOP |

| • | QRA for identifying and quantifying the Individual & Social Risk |

| • | Pre start-up Safety review conducted during commissioning phase |

|

Risk was reduced by installing lifelines, walkways & handrail ensures ease of access & safe working environment for those working at this location |

| • | The objective of the project on Highly Hazardous Raw Material handling at plants to ensure Zero exposure to people, Zero property damages. |

| • | "Process & practices to be followed w.r.t. usage, new raw material introductions, safety requirements & PPEs". |

| • | The objective of the project on "Zero Electrical incident has pulled us out of conventional ways of maintenance techniques and think for something associated to" Continuous monitoring with remote accessibility/updating-IIOT solutions. |