Learning From Incidents

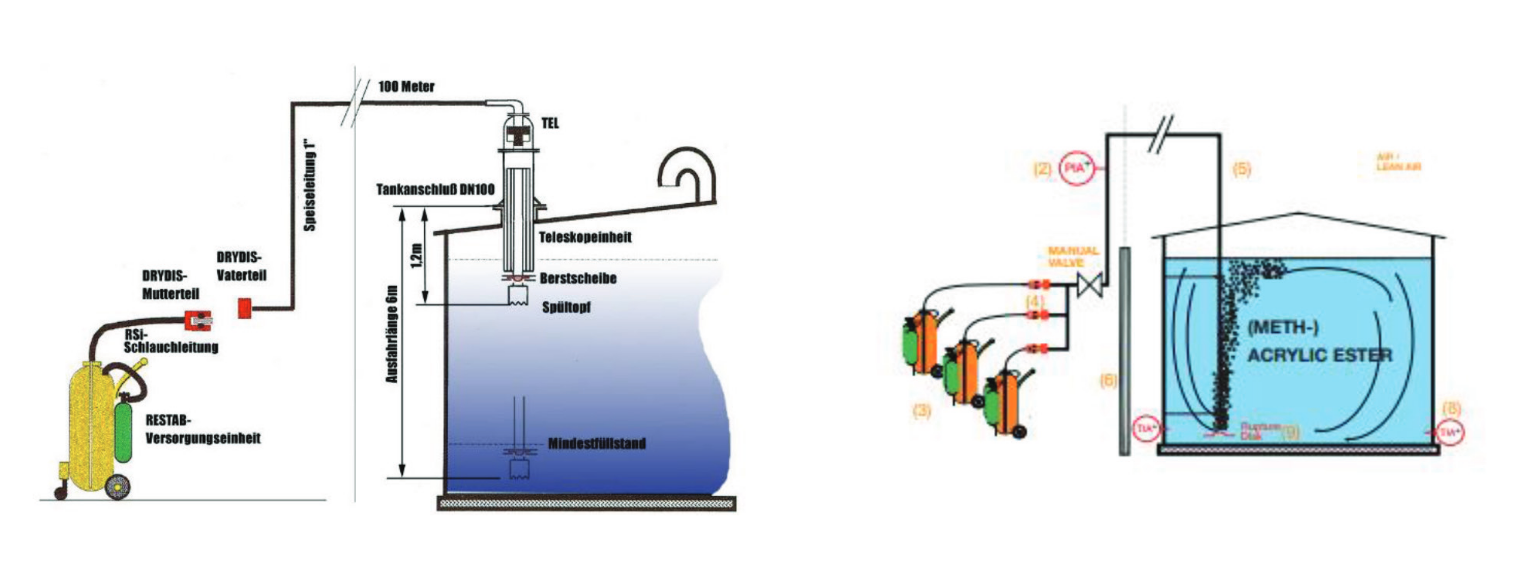

Installation of RESTAB technology for emergency restabilisation

Emergency Restabilisation with Restab Technology

The ease of use of the storage inhibitors bears the risk that accidentally the storage inhibitors might get switched off. This can be caused by contamination, oxygen depletion or excessive heat. This will eventually unfold the high reactivity of the acrylic monomer at a location where it is not intended and where there are no technical means to handle that kind of reactivity. Uncontrolled polymerization is rapid and can be very violent, generating large amounts of heat which increases the pressure. This increase in pressure causes the ejection of hot vapor and polymer which may auto ignite.

The RESTABTM system short stock inhibitor injection is designed as a secondary defense for situations where primary safety control devices have failed or where unforeseen circumstances have created a critical situation. However, it is not meant to be a substitute for good preventive safety programs. Restabilization with PTZ inhibitor is considered the very best emergency response for an uncontrolled polymerization, such as the ones caused by accidental overheating or accidental depletion of dissolved oxygen/stabilizer. Early detection of unsafe conditions inside or around the tank is a key task for a timely restabilization. All tanks must be equipped with redundant temperature probes, temperature indication, recording and several alarm levels must be implemented.