Water is a critical resource for our business operations and, therefore, a material topic.

Water stewardship is an essential element of our sustainability efforts at Asian Paints. As a

responsible paint manufacturer, we bring together water conservation, quality management,

and community engagement to safeguard this resource. We have developed a comprehensive

water management strategy that includes risk assessment, water conservation, and

replenishment both within and outside our factories.

Our sites in India are assessed on water stress risk in line with guidance from the Central

Ground Water Board (CGWB) groundwater block classification as recommended by SEBI under

BRSR disclosure. As of 31st March 2024, none of our manufacturing plants falls under the

water-stressed area as per assessment report released by Central Ground Water Board (CGWB)

in December 2022. Further, as part of the climate risk assessment, we evaluated RCP 4.5 and

RCP 8.5 scenarios for all our decorative paint manufacturing locations. The outcome of that

has been discussed in the climate adaptation section.

Across our operations, water withdrawal occurs through two primary sources: groundwater and third-party water. We have augmented rainwater harvesting capacity within the plant in the form of reservoirs which than being used in our processes. A part of the total water withdrawn is used in the product, while the remainder is directed towards domestic, utility, and gardening purposes. Our worldclass water treatment infrastructure, along with our dedication to water reuse and recycling within the premises, ensures Zero Liquid Discharge (ZLD).

During the year, we consumed 1,125

megalitres water in our decorative paint

manufacturing units. At the standalone

level, we withdrew 1,334 megalitres of total

water including harvested and consumed

67 megalitres of rainwater. The water

withdrawal with Total Dissolved Solids

>=1,000 mg/L was 6.3 megalitres.

At Asian Paints, we have undertaken extensive efforts to drive

water conservation within our plants. Conservation efforts

within our factories comprise of use of contextualised indicators

to monitor efficiency, rainwater utilisation, maximising reuse

& recycling, and adoption of innovative technologies. These

efforts are ably supported by awareness campaigns and

trainings towards water conservation and efficiency.

Harvesting and utilising rainwater in our processes is an

important focus area along with efficiency improvement.

However, during the year, lower rainfall across different plant

locations resulted in the reduction of rainwater use in plants.

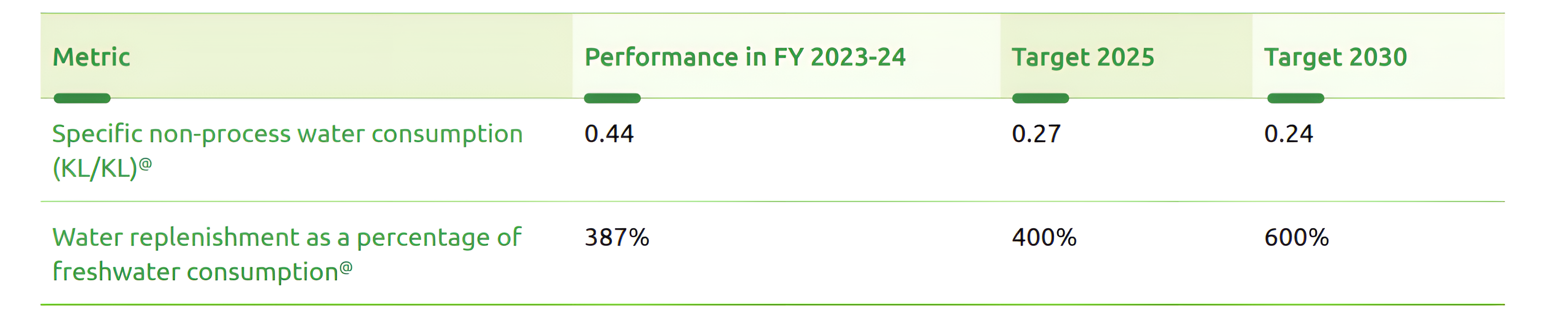

For over a decade now, we have been focussing on the

reduction of our non-process water consumption. Our efforts

have resulted in a reduction of specific non-process water by

54% from the baseline year of FY 2013-14.

The water consumption for the year includes increased

consumption on account of expansion projects in multiple

existing sites. Additionally, the lower rainfall during the year

resulted in increased consumption on account of cooling and

gardening requirements as compared to previous years.