At Asian Paints, the concept of Nature Positive reflects our comprehensive and forward-looking approach to sustainability. It signifies our commitment to assessing and minimising the environmental impact of our operations while actively contributing to ecological well-being. This theme encompasses key initiatives focussed on waste reduction, air emissions control, and biodiversity preservation – driving positive outcomes for both our business and the planet.

Waste Management

Our approach to waste management is built on systematic monitoring of material flows and regular reviews to identify opportunities for reduction. We follow a clearly defined waste hierarchy, prioritising innovative technologies for minimisation and investing in R&D to support carefully designed reuse schemes.

We continue to empower our workforce through targeted training on waste reduction techniques and safe handling practices. Our primary objective is to minimise waste generation at source by optimising existing processes and adopting more efficient production methods. Where avoidance is not feasible, we actively pursue recycling and reuse options within our operations. For example, we repurpose wash water, recover solvents and produce economy-grade paint from recycled materials.

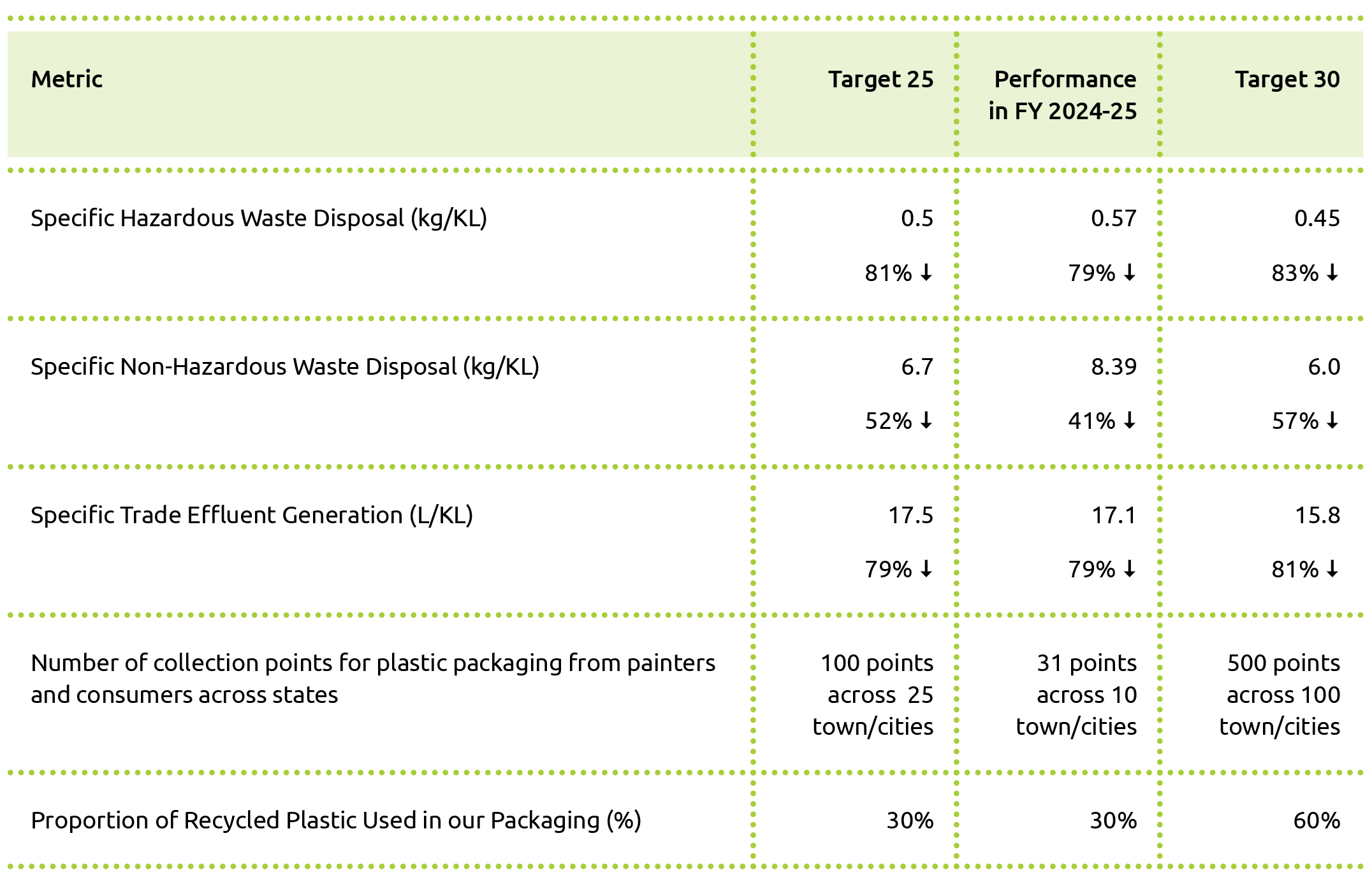

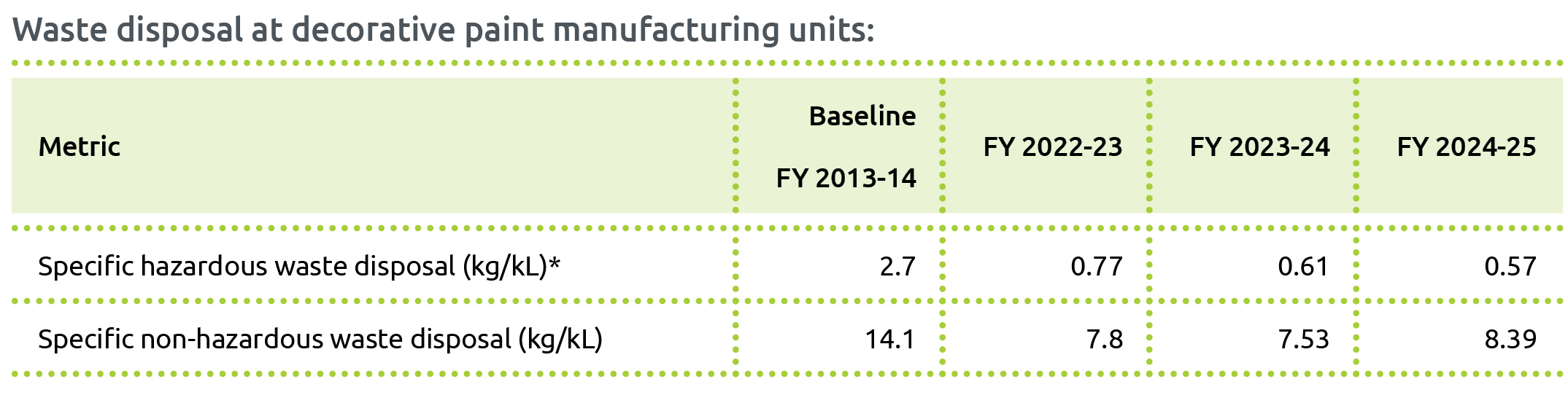

We maintain rigorous waste management protocols to ensure the safe, responsible, and environmentally compliant disposal of non-recyclable and non-reusable materials. At our paint manufacturing facilities, specific hazardous waste disposal (measured in kg/KL) has shown consistent year-onyear decline since the baseline year of FY 2013-14. In the reporting year, we achieved a further 5% reduction over the previous year, marking a cumulative 79% decrease. Specific non-hazardous waste has also reduced by 40% since FY 2013-14. However, the reporting year saw a onetime exceptional disposal of non-hazardous waste linked to expansion activities.

*The indicator includes disposal of waste under Hazardous Waste Management Rules except barrels and containers which are disposed in numbers as per authorisation.

Wastewater Management

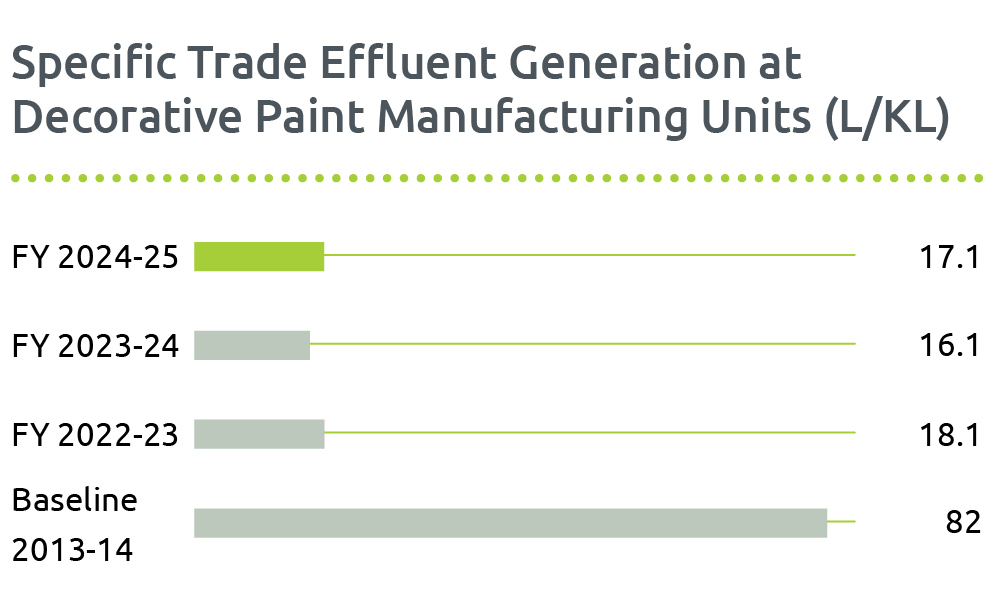

Our wastewater management approach for paint processing, equipment maintenance, and pipeline cleaning is built on two key pillars: source reduction and recycling & reuse.

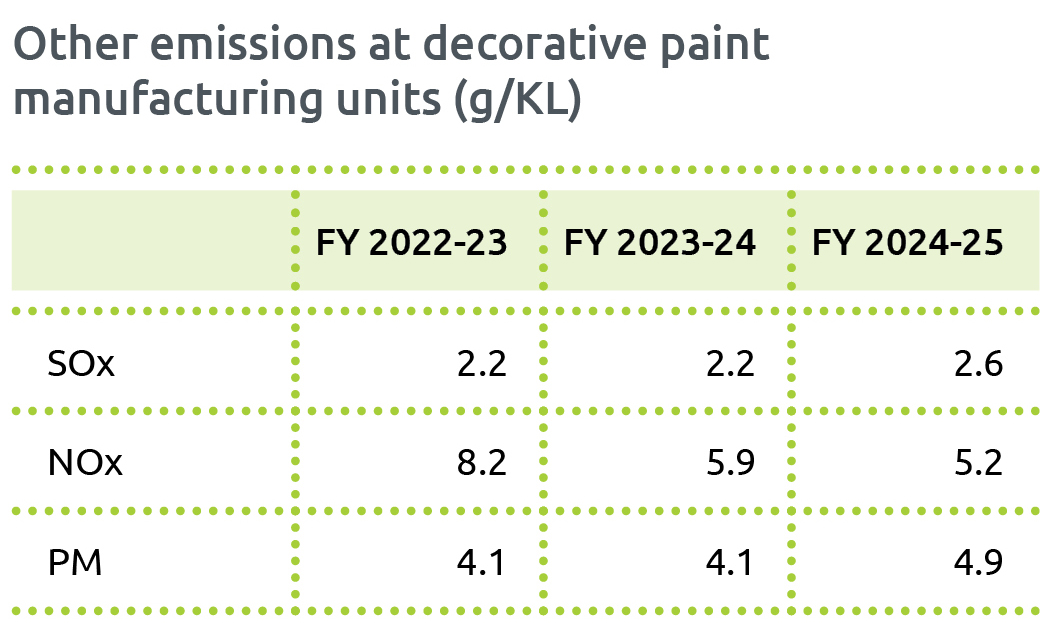

Other Emissions

We have undertaken several initiatives to refine our operational processes, including the retrofitting or replacement of diesel-based DG sets with gas-based alternatives. Boiler usage has also been moderated through the use of community steam boilers and heat recovery systems. We prioritise use of cleaner fuels such as natural gas

In our decorative paint units, absolute emissions were recorded at 3.2 metric tonnes (MT) of SOx, 6.6 MT of NOx, and 6.1 MT of particulate matter (PM). At the standalone level, emissions stood at 10.8 MT of SOx, 45.8 MT of NOx, and 15.1 MT of PM.