Energy Conservation & Emission Reduction

Our fundamental approach consists of reducing energy consumption and emissions in our operations, while improving efficiency and quality in production. Some key initiatives taken across our manufacturing locations are:

Initiative -

Replacement of conventional cowl disc with small diameter and double suction cowl disk in our twin shaft disperser equipment.

Location -

Vizag, Ankleshwar and Sriperumbudur

Outcome -

Power savings- Expected to reduce by 10-15 % for the TSD

Initiative -

Introduction of a new 2-ton electrical boiler which will help us utilize the additional wind power units generated during the peak month and also reduce the fuel consumption during that period.

Location -

Khandala factory

Outcome -

Fuel and power savings- 16289 kg of LNG fuel saved in FY20-21

Initiative -

Introduction of a heat pump for heating water for process requirement leading to reduction in usage of boiler.

Location -

Sriperumbudur

Outcome -

22000 kg of LPG fuel saving per year

|

Installation of wireless AC controller- Rohtak and Ankleshwar Benefit- Power consumption reduction of 25000 units per year |

|

Air leakage reduction across all factories- Average reduction from 35% to 29% |

|

Patancheru- Reusage of exhaust air of AODD pump. |

|

Optimized usage of utilities- Stoppage of CT-2 and operation of industrial reactor and R-7 on CT-7 -Kasna |

|

Vacuum pump utilization, packing pick and place activity, presently generated through pressurized air. Vacuum pumps help saves electricity (Vacuum pumps in place of vaccum ejector (air operated) installation for packing in Rohtak Benefit- Power consumption reduction by around 1250 units per month |

|

Cooling tower High grade E-glass epoxy energy efficient fan commissioning reduced power consumption by 35-40% in Mysuru due to Adoption of new technology. |

|

Sigma Controller installation for Air compressor system in utility- To cater the variable air load requirement of Rohtak plant in optimized manner, sigma air controller has been installed and integrated with air compressor system for auto switching operations of compressors as per the type and demand and thus helping in reduction of base power load of compressor units. The system has been programmed with logic so as operate as per the load and capacity of individual compressor units. Benefit- Power consumption reduction by around 350 units per day. |

|

FIBC load cell based powder conveying- Improves powder conveying rate from FIBC(flexible intermediate bulk container) to the silo at Sriperumbudur plant. Benefits- Powder Conveying rate has increased around 30% from old level, capability increase –2036 bags per month for certain operations, specific power consumption saving for the silo is approximately 450 units per day (1 SPC per day) |

|

LNG and Green Fuel |

During FY 2015-16, RE36% was our goal for 2020. It was a flagship initiative which demonstrated our commitment towards sourcing clean energy.

Since then we have substantially augmented our investments in renewable energy to reduce dependence on fossil fuels.

We achieved RE footprint of 57% in FY 2020-21

Solar Tree

Rooftop Solar

Khandala plant during the peak months has excess renewable energy units generation which were unused till last year. Considering the under utilized excess units, we came up with the boiler which will run on electricity. This will help us in the fuel saving during the peak months of Renewable energy generation. The saving in terms of reduced fuel consumption due to the electrical boiler is of 15 Lacs.

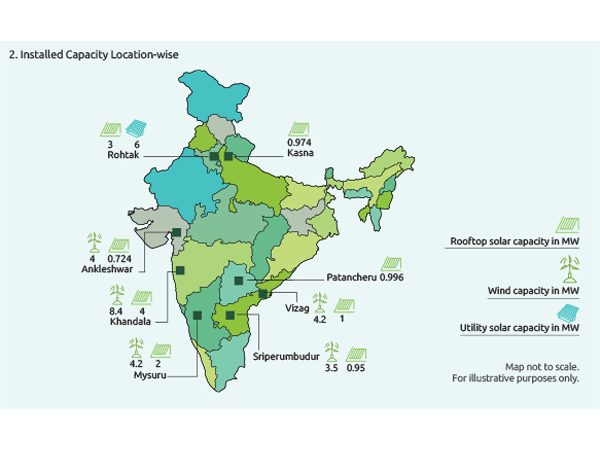

To enhance the RE capacity of Rohtak plant,

6 MW

utility solar plant has been installed

RE Wind Power Portfolio Percentage Contribution of

38.26%

• 20.10 MW of installed capacity

• 26 million units consumed in FY 2020-21

RE Solar Power Portfolio Percentage Contribution of

18.02%

• 13.51 MWH of installed capacity

• 15.7 million units consumed in FY 2020-21

Emissions in the paint industry stem from various sources such as the manufacturing process, filling and cleaning activities, mixing, storage of solvents and paint application. During the last few years, we have been able to reduce our emissions by use of alternate fuel, improving our energy efficiency and enhancing our renewable energy portfolio.

Since FY2013-14, our Scope 1 emissions have reduced by

54%

while Scope 2 emissions have come down by

39%