Water is a critical resource for Asian Paints and a cornerstone of our environmental sustainability strategy. As a responsible manufacturer, we are committed to using water efficiently, safeguarding its quality, and ensuring its long-term availability–for both our operations and the communities in which we operate.

Our integrated water management approach encompasses risk assessment, conservation, efficiency enhancement, and replenishment. This strategy is implemented across our B manufacturing facilities and extended to surrounding regions through targeted community engagement and localised interventions. We actively collaborate with stakeholders to promote responsible water use and strengthen resilience against water-related risks.

In alignment with SEBI's Business Responsibility and Sustainability Report (BRSR) disclosure requirements, we conduct water stress assessments at all Indian manufacturing locations using the Central Ground Water Board's (CGWB) groundwater block classification. According to the CGWB's 2024 assessment, the groundwater block encompassing our Patancheru facility has been designated as water stressed as of 31st March 2025.

To further strengthen our adaptive capacity, we have conducted climate risk assessments for all decorative paint plants using Representative Concentration Pathway (RCP) 4.5 and RCP 8.5 scenarios. These assessments help us anticipate long-term water-related risks and inform strategic planning for climate resilience.

Optimising Water Usage at Asian Paints

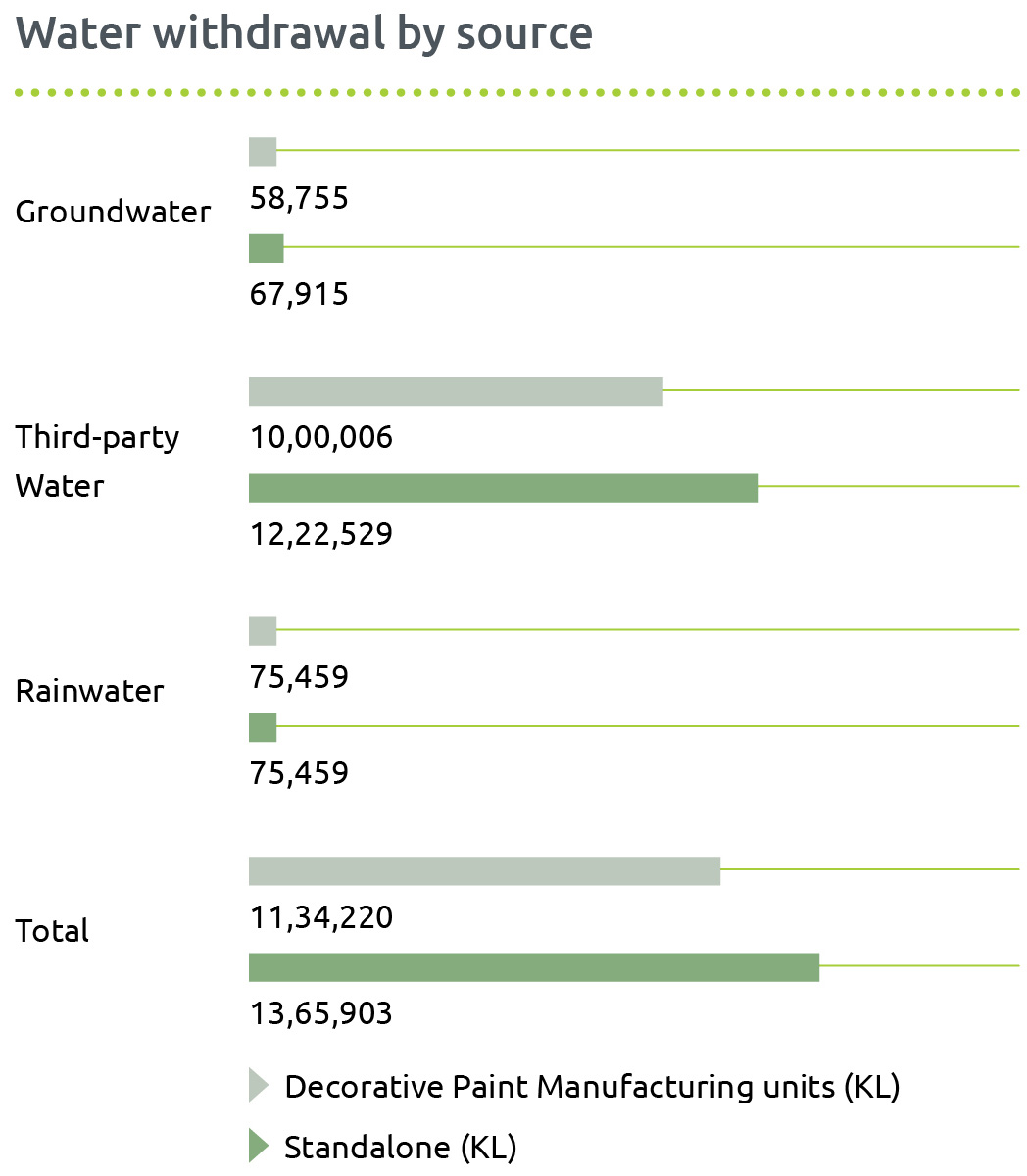

We continue to make steady strides in managing water resources responsibly across our operations. Water is primarily withdrawn from two sources – groundwater and third-party suppliers. In addition, we have significantly enhanced our rainwater harvesting capacity through the construction of reservoirs within our premises, enabling us to supplement process requirements with harvested water.

A portion of the withdrawn water is consumed into our products, while the rest is utilised for domestic, utility, and landscaping purposes.

Our advanced treatment systems, combined with a strong focus on reuse and recycling, enable us to maintain a Zero Liquid Discharge (ZLD) status across our manufacturing sites – an achievement that reflects our continued emphasis on water stewardship.

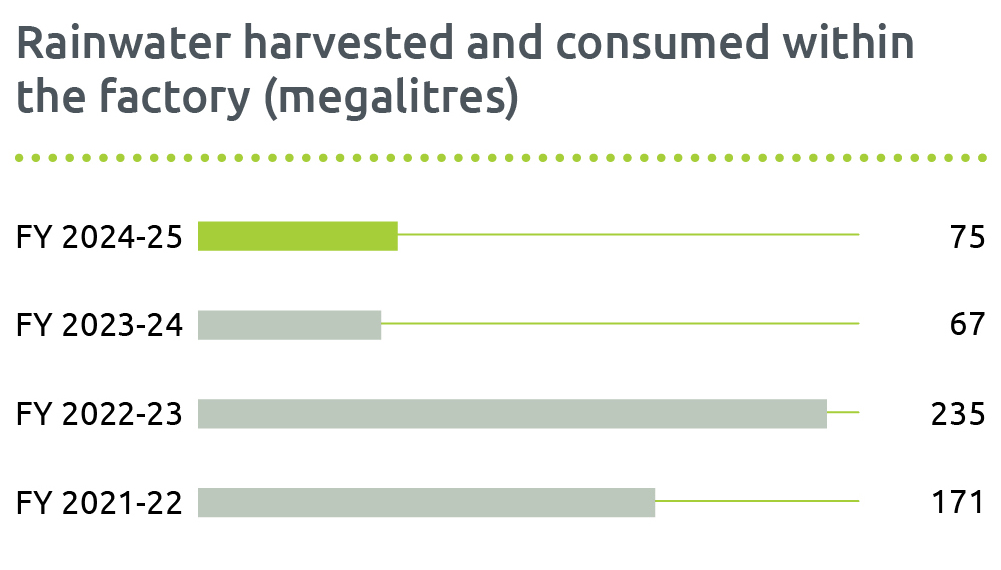

In FY 2024-25, our decorative paint manufacturing units consumed 1,134 megalitres of water. At the standalone level, total water withdrawal stood at 1,366 megalitres, including 75 megalitres of harvested rainwater. Notably, only 5.4 megalitres of water withdrawn had Total Dissolved Solids (TDS) ≥1,000 mg/L.

Water Replenishment and Conservation Inside Factory Premises

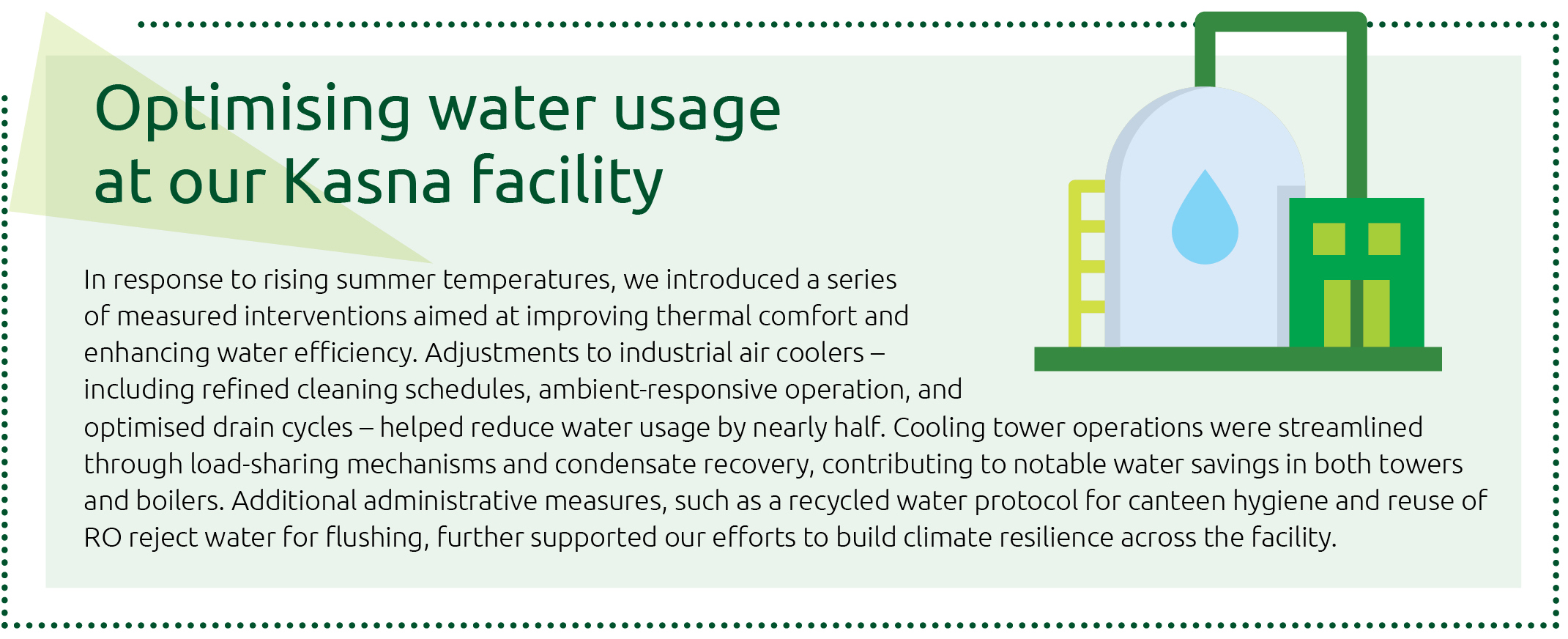

We have consistently prioritised water conservation across our manufacturing sites, undertaking a range of initiatives to drive efficient and sustainable use. Our approach includes the use of contextual indicators to monitor water efficiency, maximise reuse and recycling, and integrate innovative technologies into everyday operations. A key focus has been the harvesting and use of rainwater within our processes - an area where we continue to make encouraging progress. These interventions are complemented by ongoing awareness campaigns and training programmes that promote a culture of conservation and responsible usage among employees.

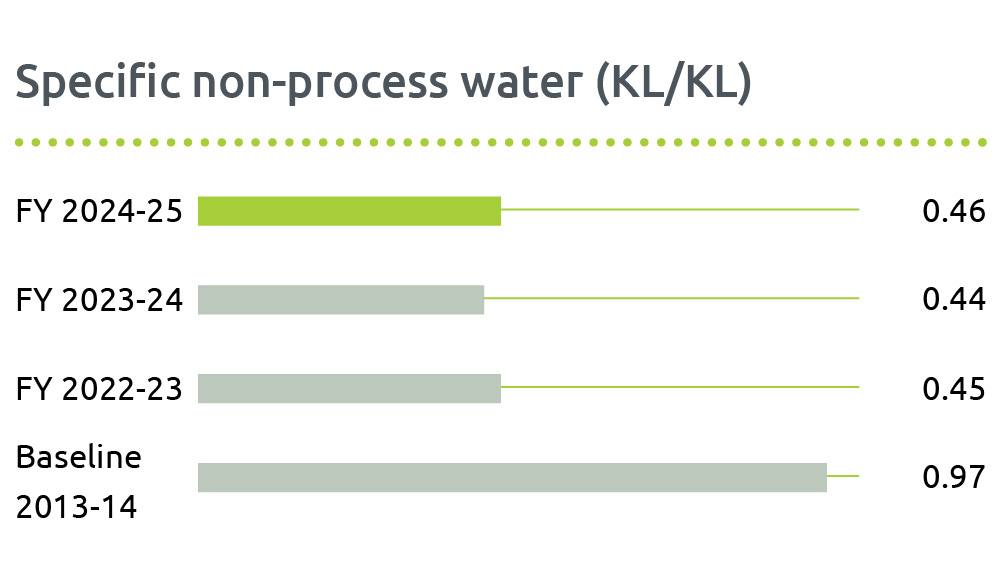

Non-Process Water Consumption at our Decorative Paint Manufacturing Units

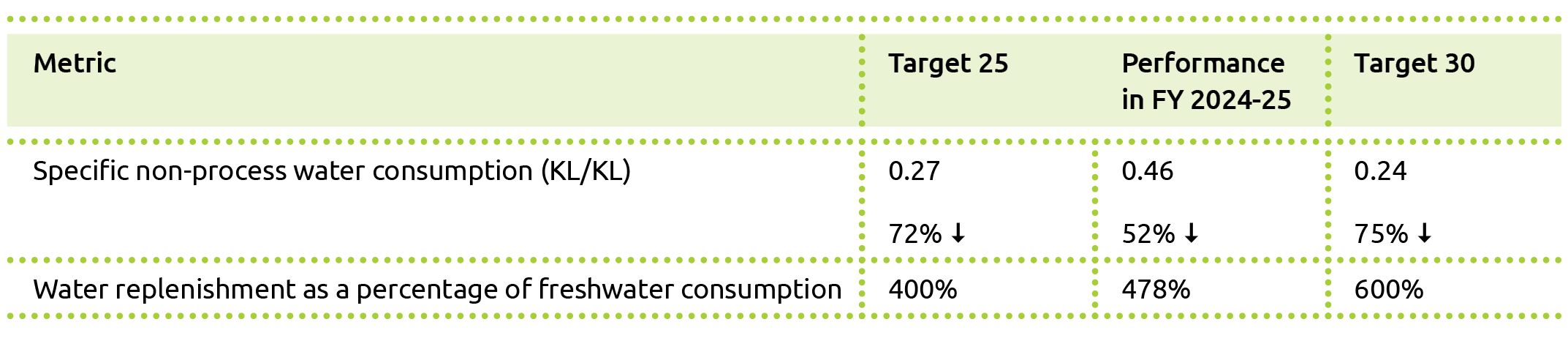

Over the years, we have maintained a strong focus on reducing non-process water consumption across our operations. As a result of these sustained efforts, we have achieved a 52% reduction in specific non-process water usage compared to our baseline year of FY 2013-14. While this year saw a temporary increase in specific non-process water consumption due to expansion and backward integration projects, our overall reduction from the baseline remains significant at 52%.

Water Replenishment and Conservation Outside Factory Premises

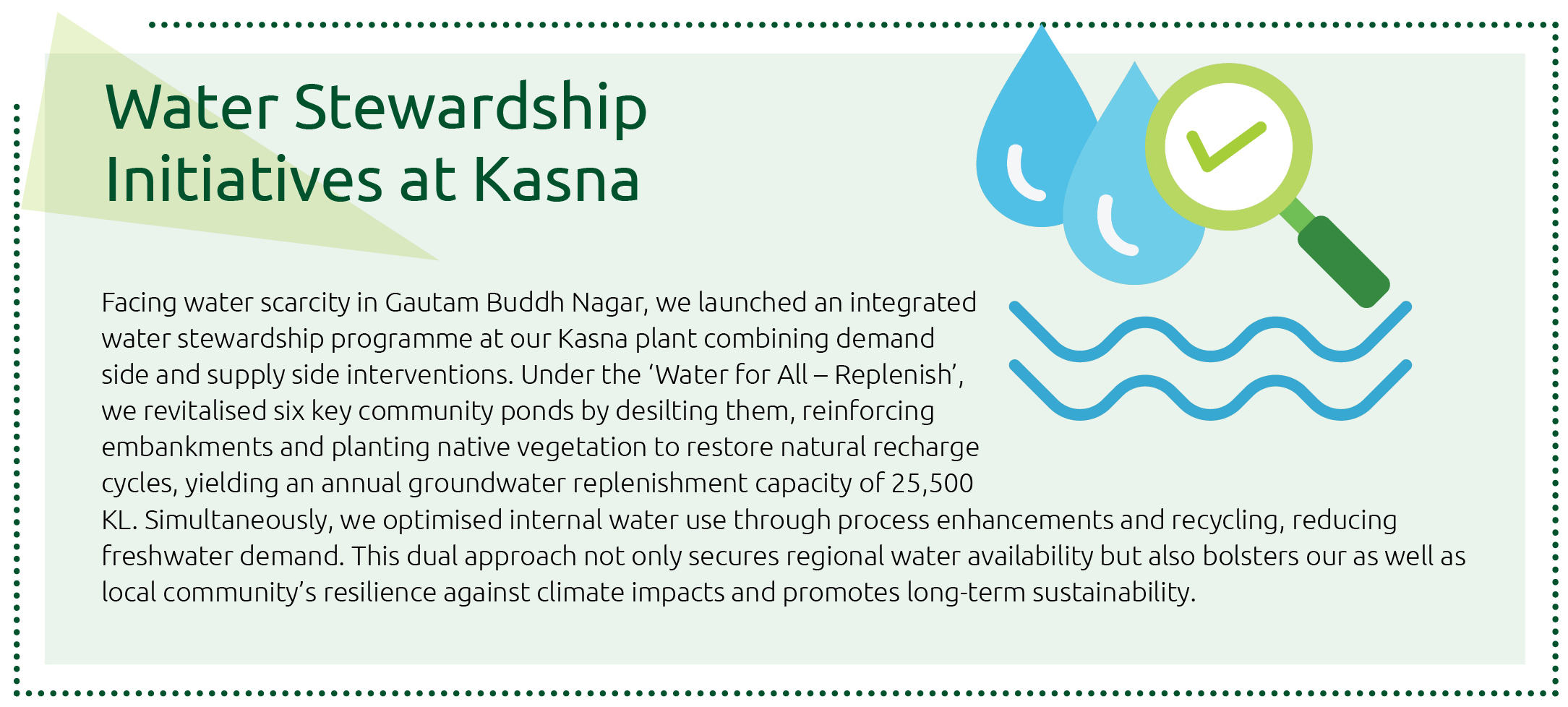

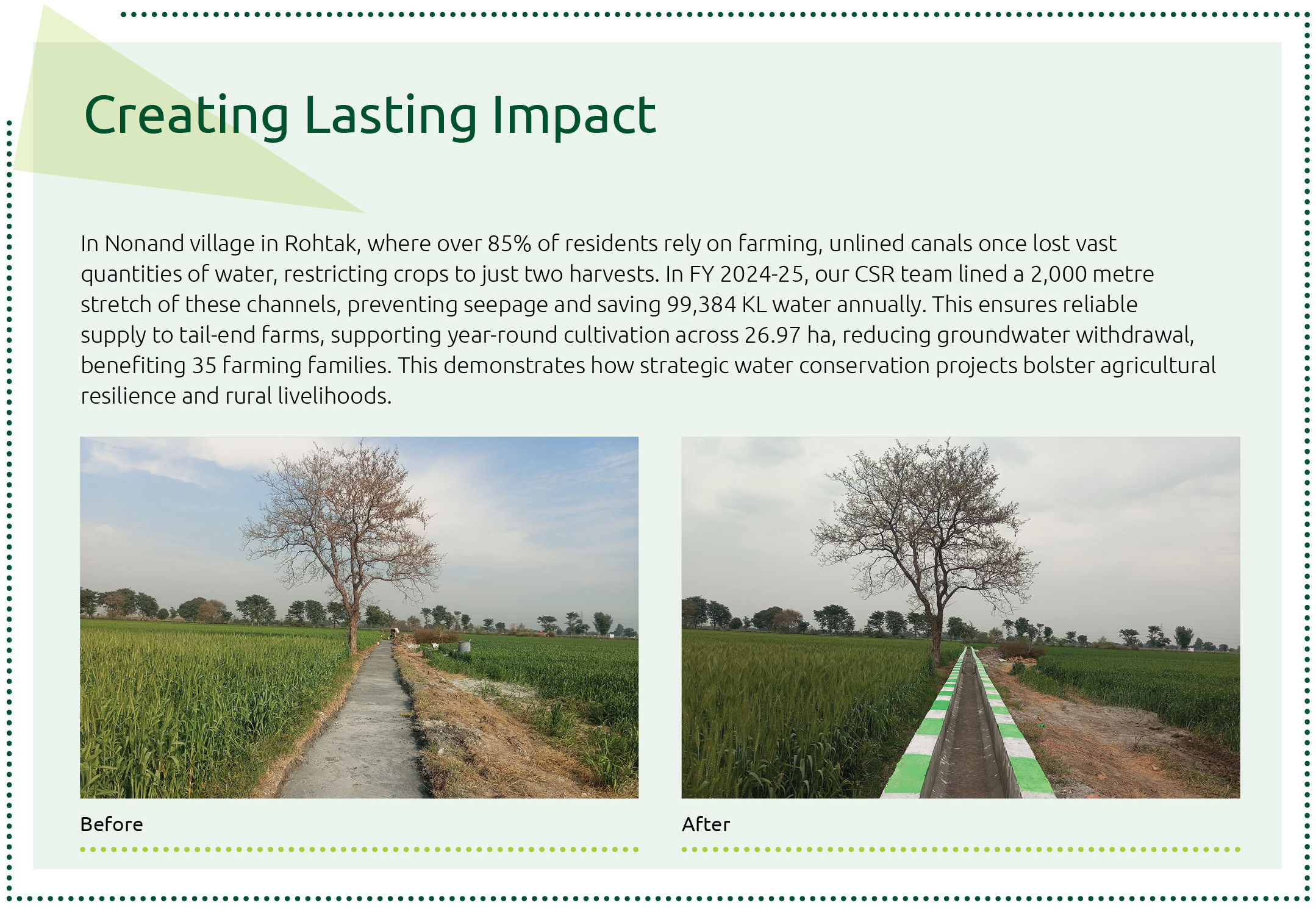

We actively collaborate with local communities to enhance water availability in the regions surrounding our manufacturing facilities. This is achieved through a combination of supply-side interventions – such as pond rejuvenation and canal lining – and demand-side measures, including integrated watershed management and silt application. These efforts are further supported by farmer training programmes that promote sustainable water practices.

During the reporting year, our sustained investments enabled us to replenish 478% of the freshwater consumed at our paint manufacturing sites. These initiatives not only bolster essential ecosystem services but also improve water access for domestic use, agriculture, and groundwater recharge.

The details of the community water interventions undertaken during the year can be found in the community section of this report.