We acknowledge climate change as a significant global challenge with profound implications for our operations, supply chain, and stakeholders. Our response is rooted in proactive mitigation and adaptation strategies designed to minimise our environmental impact and strengthen long-term business resilience.

As part of our structured decarbonisation pathway, we are focussed on reducing Scope 1 and Scope 2 greenhouse gas emissions. Guided by our ESG roadmap, we have established ambitious emissions reduction targets. While the journey presents challenges, it has also fostered internal capability development and embedded long-term planning across our operations.

To address broader climate-related risks, we have completed a comprehensive Scope 3 emissions inventory and continue to advance our Sustainable Supply Chain Programme, aimed at mitigating environmental impacts across our value chain.

In alignment with the Task Force on Climate-related Financial Disclosures (TCFD) recommendations, we conduct climate scenario analyses and risk assessments. These tools help us identify vulnerabilities and enhance our adaptability to evolving climate conditions, ensuring we remain responsive and resilient in a changing world.

Climate Change Mitigation

Our commitment to climate action is grounded in a comprehensive assessment of emissions across both our operations and broader value chain. Operational emissions primarily stem from fuel and electricity consumption, while value chain emissions are largely associated with transportation and upstream supplier activities.

Recognising that energy and resource use are key contributors to our carbon footprint, we are actively implementing a decarbonisation strategy that targets both direct and indirect emissions. This strategy is supported by key enablers that drive progress through innovation, collaboration, and continuous improvement.

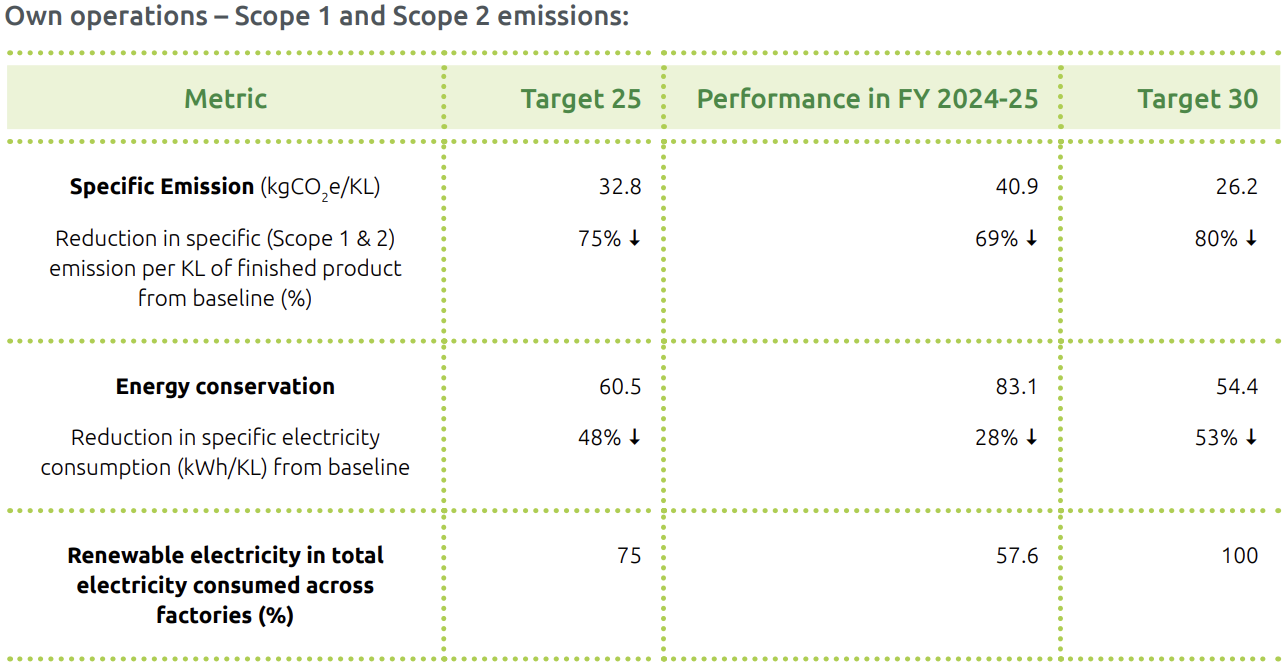

We have made consistent progress in recent years, particularly in advancing energy efficiency and renewable energy initiatives. While performance in 2025 has been mixed due to a range of external and operational factors, we continue to build on the strong foundation laid and remain focussed on our long-term climate objectives.

Our decarbonisation journey is dynamic and evolving, with a strong emphasis on scaling effective solutions, leveraging emerging technologies, and sustaining momentum toward a low-carbon future.

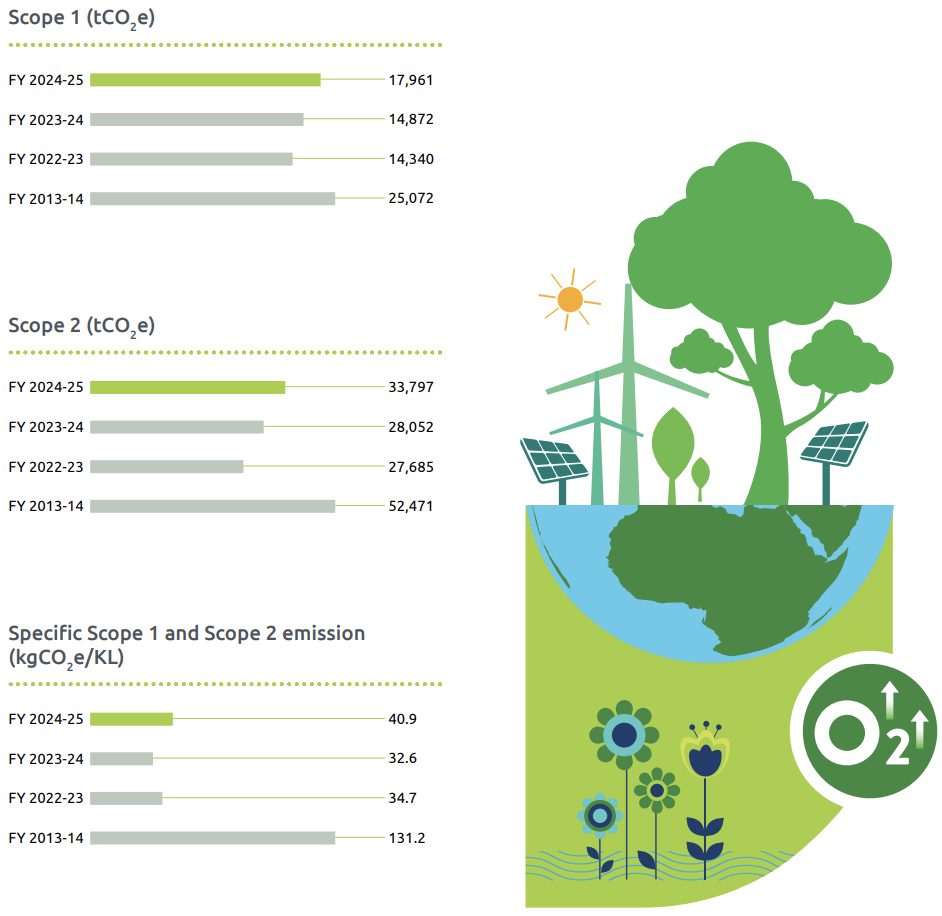

Over the years, we have made steady progress in reducing absolute Scope 1 and Scope 2 emissions within our decorative paints business. Since FY 2013-14, Scope 1 emissions have declined by 28%, and Scope 2 emissions at our manufacturing units have reduced by 36%. Emission intensity has also seen a notable decrease of 69% from the baseline year. These improvements reflect the cumulative impact of ongoing energy efficiency measures and increased adoption of renewable energy across our operations.

During the year, we witnessed an increase in specific emission from the reducing trend,due to increase in absolute Scope 1 & Scope 2 emissions and lower-than-expected production volumes. Scope 1 emissions rose due to higher fuel consumption associated with backward integration and expansion activities across multiple facilities. Scope 2 emissions increased as a result of elevated energy demand from these projects, while renewable electricity consumption remained steady. While most of these impacts are transitional and expected to stabilise, some are more enduring. We are actively working to identify and implement mitigation pathways to address the latter.

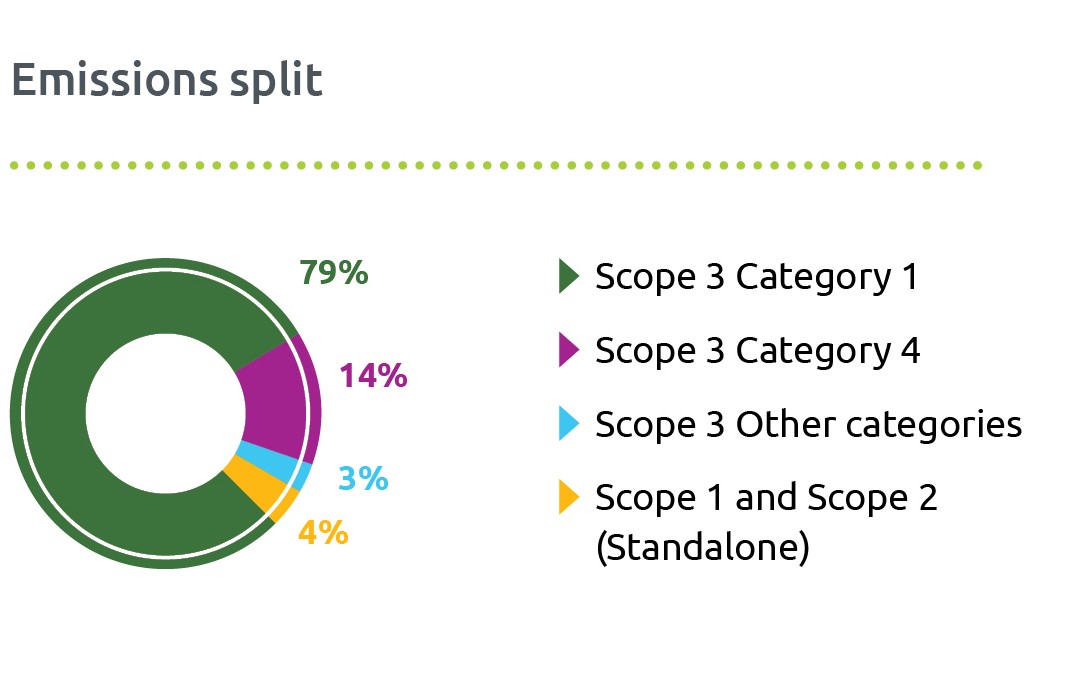

The Scope 1 and Scope 2 emissions on a standalone basis during the year were 87,435 tCO2 e & 52,727 tCO2 e respectively. The emission intensity was 107.6 kgCO2 e/KL. Biogenic emission due to the combustion of biofuels was 59 tCO2 e.

E1: Energy Efficiency

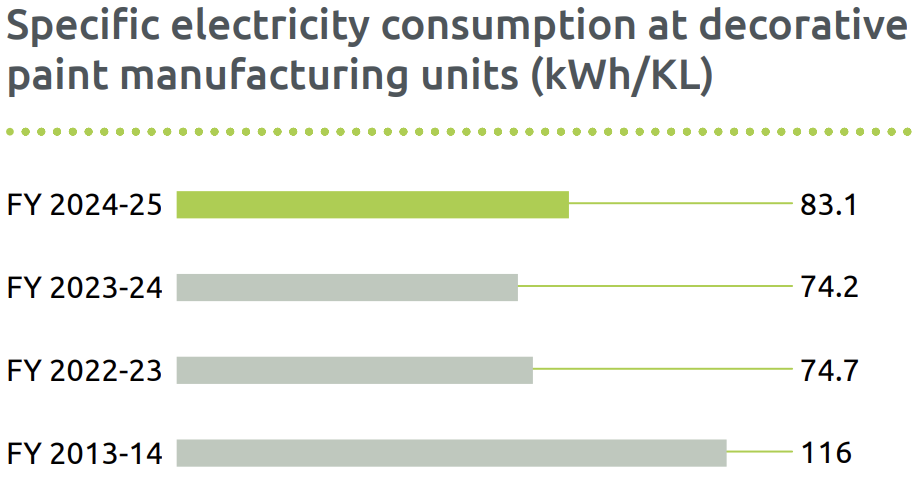

Efficient energy use remains a central pillar of our efforts to reduce Scope 1 and Scope 2 emissions. Our strategy continues to focus on process optimisation, adoption of advanced technologies, and upgrading legacy infrastructure with energy-efficient systems. These technical measures are complemented by regular training and awareness initiatives aimed at fostering a culture of energy conservation.

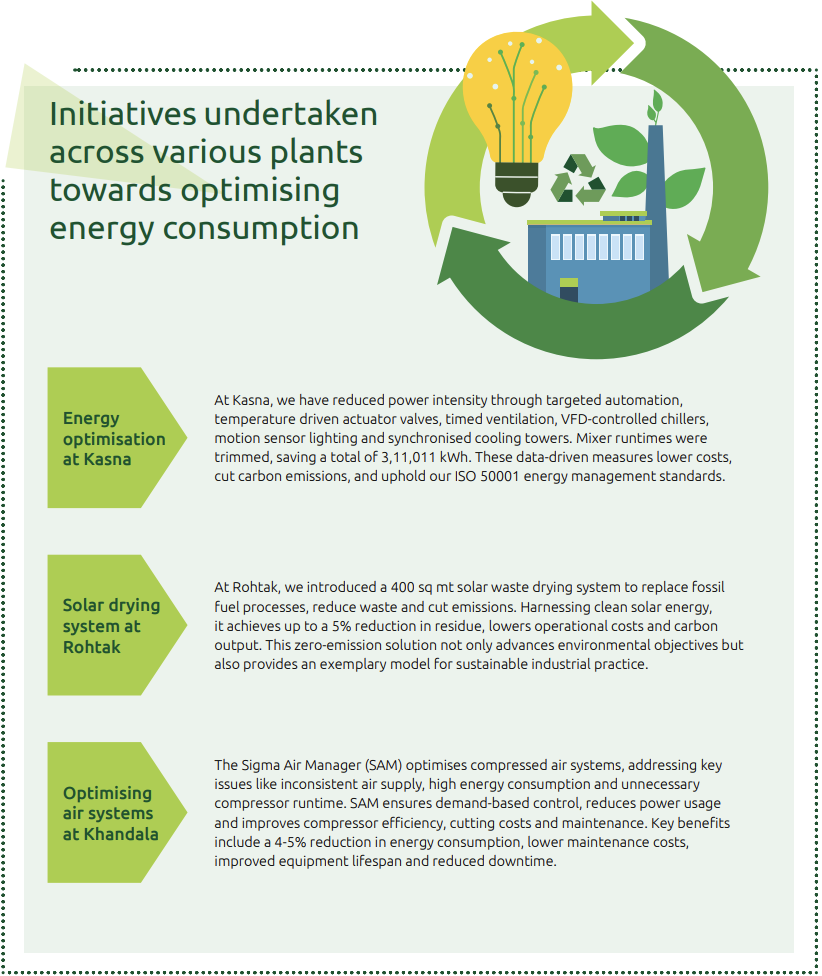

During the year, specific electricity consumption at our decorative paints' plants increased, primarily due to capacity expansion, backward integration projects, and lower than expected production volumes. Despite this short-term rise, we have achieved a 28% reduction in specific electricity consumption compared to the baseline year. This translates to an increase of 40,200 GJ in electricity consumption over the previous year, while still reflecting a net reduction of 1,49,803 GJ from FY 2013-14 levels.

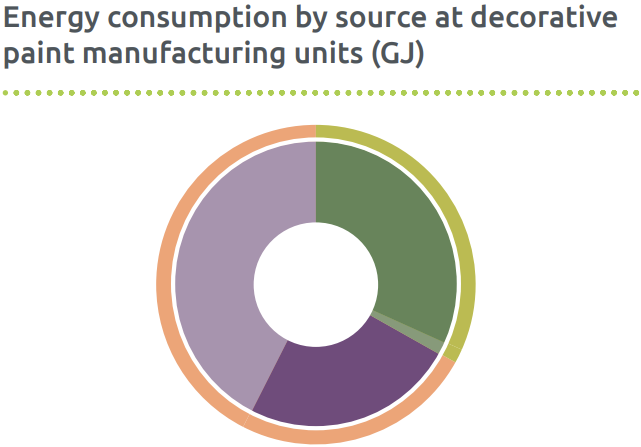

During the year, energy consumption at our decorative paint manufacturing units stood at 6,95,719 GJ, with renewable energy accounting for 2,23,793 GJ.

On a standalone basis, total energy consumption for the year was 15,25,716 GJ, comprising 10,33,343 GJ of direct energy and 4,92,373 GJ of indirect energy, including 12,251 GJ of procured steam. Energy intensity was recorded at 1.18 GJ/KL.

We continue to track operational data across all sites to identify opportunities for improvement and to optimise energy performance. A structured energy audit framework has been institutionalised to support these efforts, enabling continuous enhancement and ensuring that we stay on course towards long-term energy efficiency goals.

E2: Renewable Energy

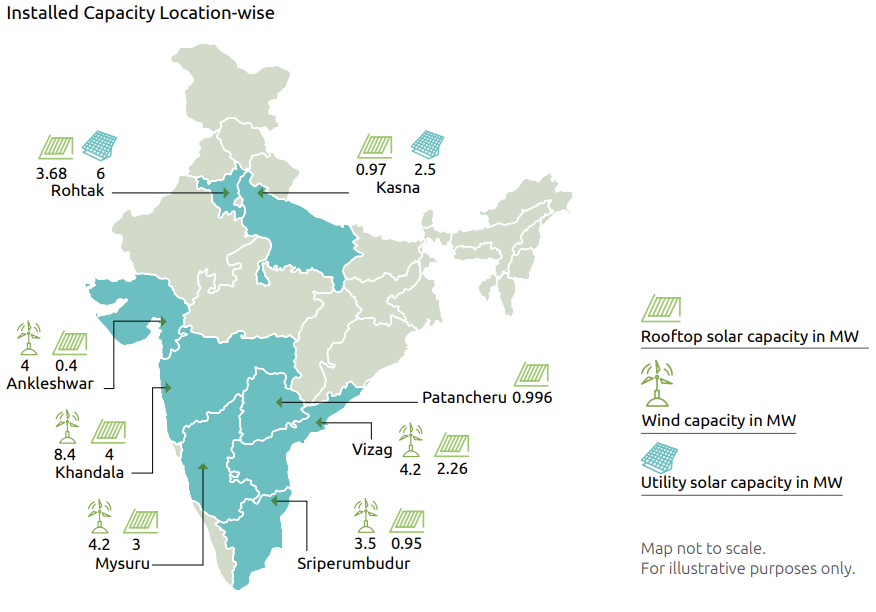

Our decorative paint manufacturing plants have an installed renewable energy capacity of 48.9 MW – 24.6 MW solar and 24.3 MW wind. During the reporting year, renewable energy met 57.6% of our electricity needs, helping us avoid approximately 45,067 tCO₂e emissions compared to the baseline year. The decline in renewable share was majorly influenced by increased electricity demand. Regulatory factors such as state policies mandating minimum grid utilisation and banking restrictions also play a role in limiting netting off of renewable energy, however the excess renewable electricity generated is fed to the grid and remains available for consumption. With ongoing initiatives nearing completion, we anticipate an improved renewable energy contribution in the coming year.

Value chain – Scope 3 emissions

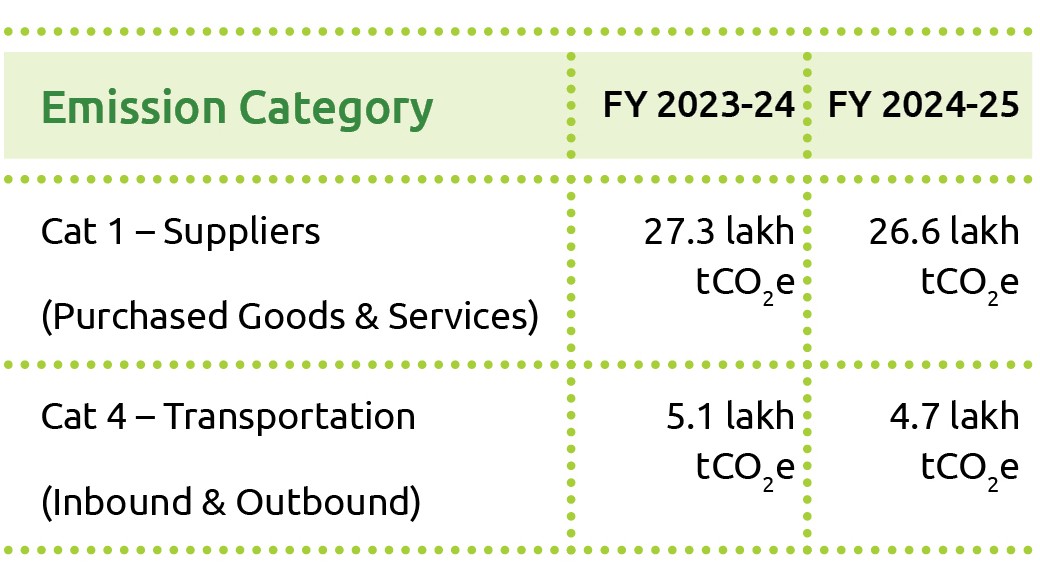

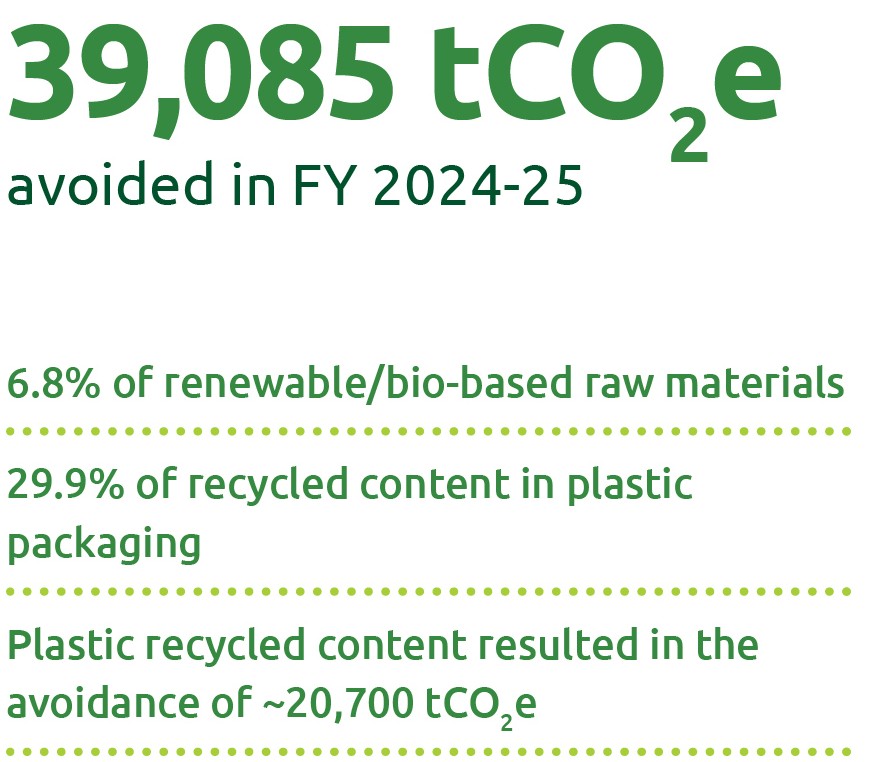

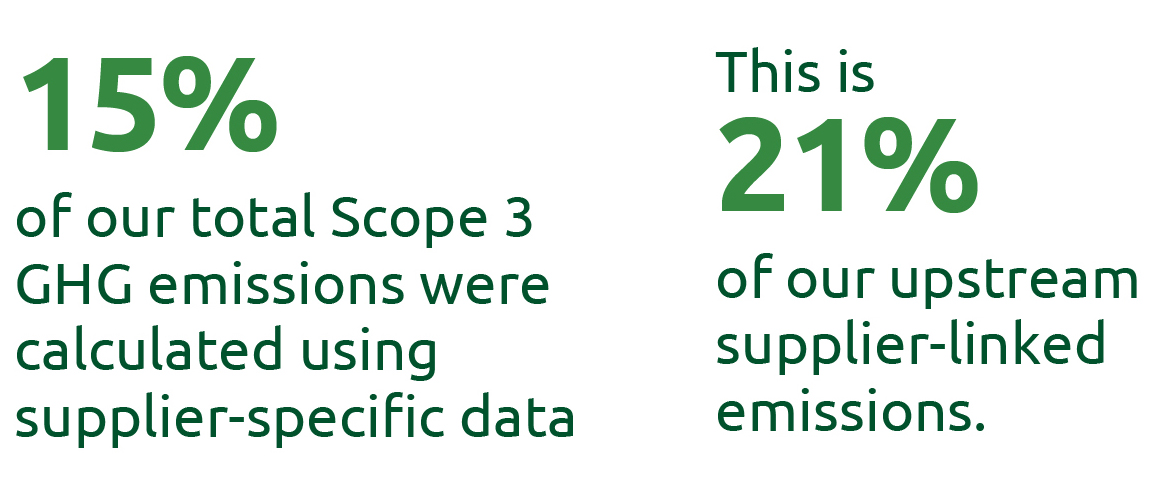

As part of our journey toward a low-carbon future, we are steadily broadening our efforts to address Scope 3 emissions. During the year, total Scope 3 emissions were estimated at 32.2 lakh tCO₂e, with supplier operations and transportation together accounting for approximately 93% of the total emissions.

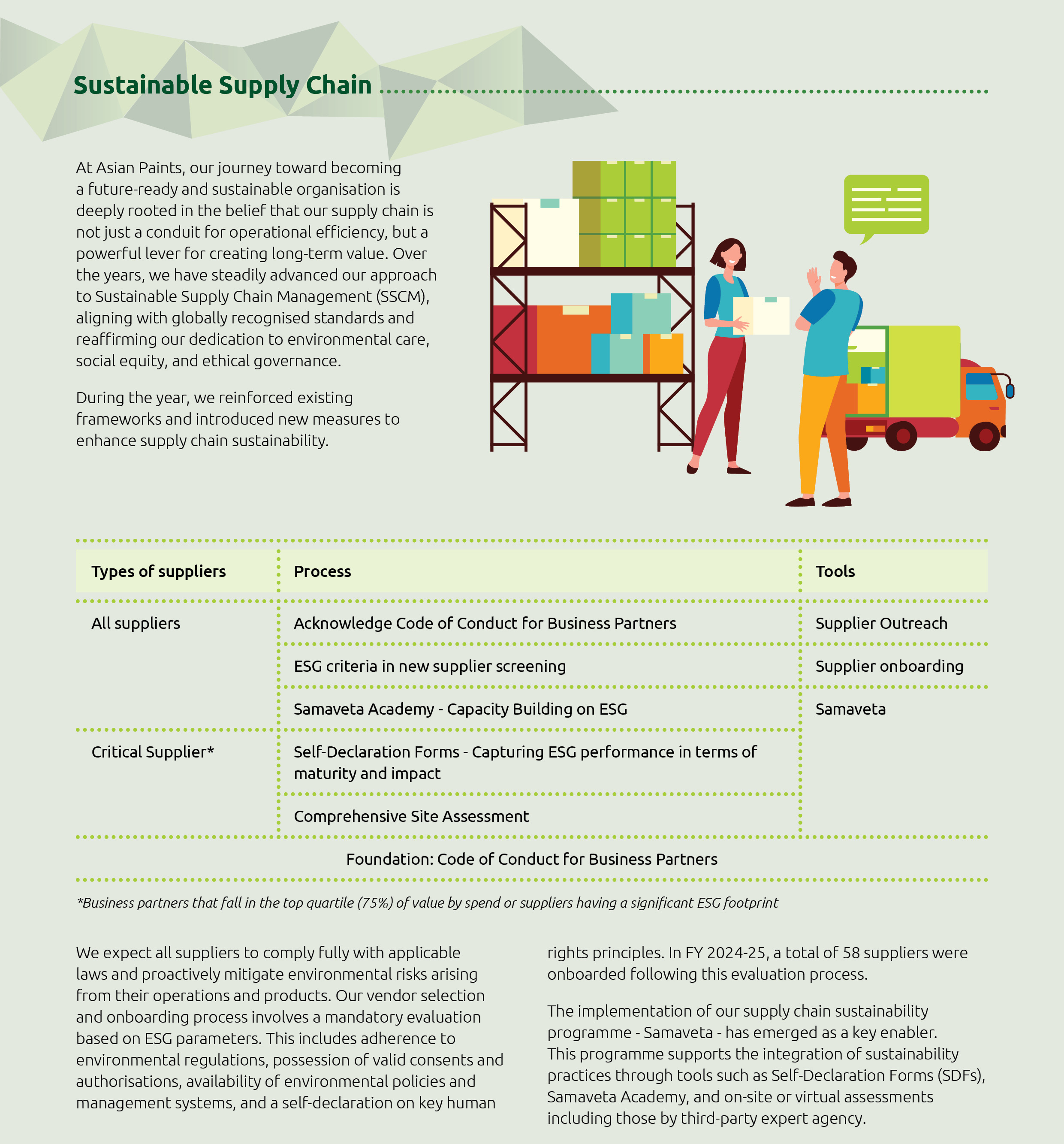

To drive decarbonisation beyond our direct operations, we are focussing on formulation optimisation, adopting low-carbon material alternatives, promoting low-emission transport, and embedding sustainability principles across our value chain. These initiatives reflect our commitment to integrating climate action into supplier engagement and operational decision-making.

We continue to refine our understanding of value chain impacts and work collaboratively with partners to identify and implement reduction opportunities. These efforts are integral to our broader climate strategy and support our longterm ambition of building a resilient, low-carbon supply chain

E3: Sustainable optimisation of products and services

We focus on formulation optimisation and efficiency to reduce the overall carbon footprint of the products. This involves reducing high emission contributing raw materials through multiple formulations and process innovations such as improving the scattering efficiency of rutile and other raw materials.

E4 - Lesser-carbon-intensive raw material alternatives

We are committed to reducing our environmental impact by evaluating and adopting raw material alternatives with lower embedded carbon. This includes exploring alternate grades and chemistries and increasing the use of renewable or bio-based content. A key initiative in this direction is our ongoing investment in establishing production facilities for low-carbon-intensive Vinyl Acetate Monomer (VAM) and Vinyl Acetate Ethylene emulsions (VAE).

E5 - Engagement with suppliers to reduce emissions

Procurement activities account for nearly 80% of our total greenhouse gas (GHG) emissions, making supplier engagement a key pillar of our decarbonisation strategy. Through our Samaveta programme, we engage suppliers on critical ESG topics, including climate change, by raising awareness, assessing performance, and promoting continuous improvement.

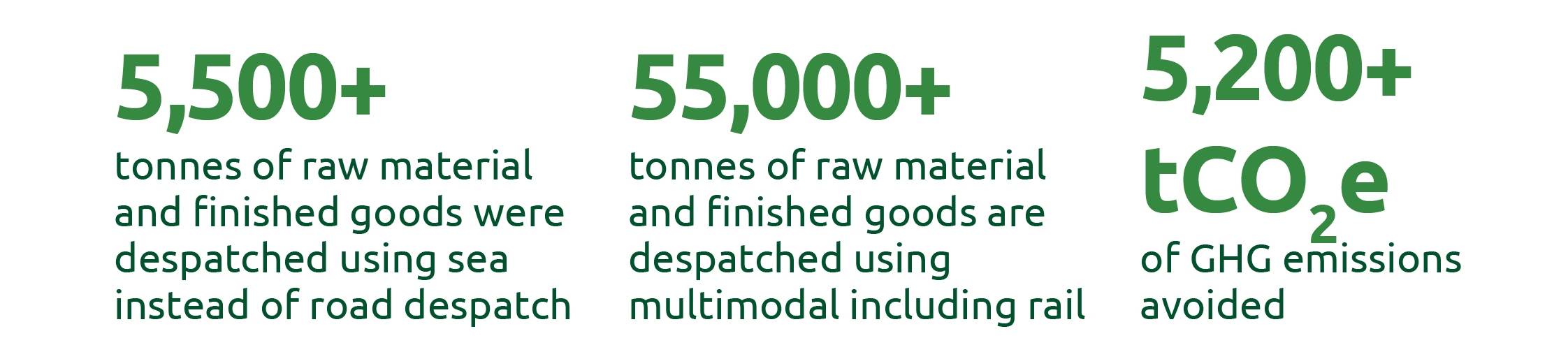

E6 - Transportation and distribution

We are consistently advancing our efforts to minimise the environmental impact of logistics by adopting greener modes of transportation and enhancing fleet efficiency. Our strategic transition towards rail and sea transport for long-haul movement, along with the adoption of low-emission vehicles, has resulted in a marked reduction in fuel usage and associated emissions.

Moreover, our collaborative initiatives with FMCG/FMCD partners to enable load pooling and reverse logistics have further strengthened distribution efficiency. We also actively explore opportunities presented by the National Logistics Policy to strengthen our green logistics framework and foster innovation in sustainable supply chain practices.

Climate Change Adaptation

In FY 2022-23, we undertook a detailed climate risk assessment aligned with TCFD recommendations, focussing on both physical and transition risks. This involved engaging internal stakeholders, identifying key vulnerabilities, and assessing the potential business impact.

Physical risk analysis

We evaluated short-term (2030) and long-term (2050) risks across our eight decorative paint manufacturing sites using IPCC scenarios (RCP 4.5 and RCP 8.5). Key climate hazards identified included heatwave, drought, cyclone and flood. While the overall risk was assessed as low, we continued to implement resilience measures such as rainwater harvesting, improved ventilation, and water conservation systems.

Transition risk analysis

We also assessed policy, legal, technological, and market risks associated with transitioning to a low-carbon economy. This evaluation was based on IEA SDS scenarios and India's Net Zero commitments. Risks included market fluctuations and regulatory changes, while opportunities were identified in energy source, product innovation and resource optimisation. Our ESG strategy enables us to proactively manage these risks and leverage emerging sustainability opportunities.

These assessments are now integrated into our Risk Management Framework, reinforcing our long-term climate resilience. Read more about our approach to risk management in our TCFD Index.